This article was published on The Daily Aztec website on May 4, 2020.

As the fight against COVID-19 leaves hospitals and intensive care units in desperate need of medical supplies, one San Diego State professor has worked to create prototypes of ventilators that could be used to treat patients suffering from coronavirus.

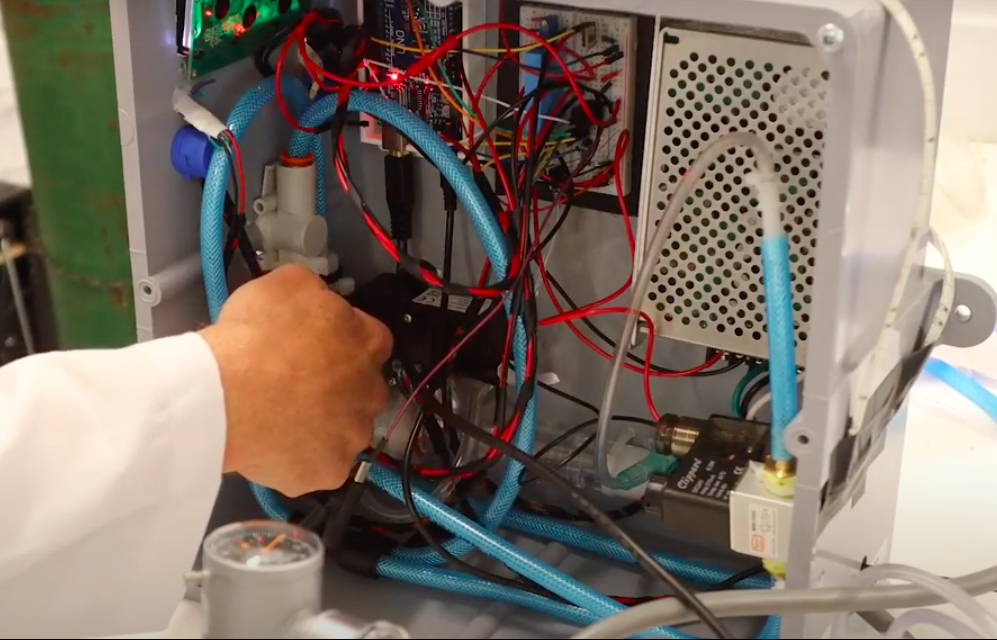

Mechanical engineering professor Kevin Wood partnered with two master’s students, Jack Lucas and Tyler Lestak, to create prototypes of ventilators with materials that can be purchased from Amazon.

Wood’s latest prototype was created after receiving feedback from local doctors on ways to improve the design.

“We are working right now with this current system that we have with local health officials to really try and make sure this system is safe, and then try and move forward,” Wood said. “So we can help in the case of an emergency where there’s a ventilator shortage, the system is ready to go and can be easily turned around to help in that crisis.”

Wood said he was inspired to start the project because of the Department of Defense Hack-a-Vent challenge to develop a low-cost, functioning ventilator at the end of a two-week period to help fight COVID-19.

“I got two students together, and we quickly worked through an idea, wrote the proposal and then when we thought we had a pretty good idea, started actually trying to build it,” he said. “In less than a week, we had a fully functioning prototype.”

Lestak said the quick turnaround process was a rewarding challenge.

“Initially, I guess it was a little daunting,” Lestak said. “He emailed me the Department of Defense project outline and we had only two days to put together a prototype, so that was a bit daunting but also exciting.

“It was good to actually feel like we were contributing to this whole pandemic.”

Wood said projects tend to move at a slower pace in the mechanical engineering world, so he was very excited to complete this project in a short period of time.

“To see this thing where we didn’t have any design to having a working design in less than a week was actually pretty exciting,” Wood said. “It was one of those things that was pretty neat to see it come to life before your eyes.”

Because Amazon uses several different suppliers, the ventilator Wood made cost about $270, whereas purchasing supplies and material all from one supplier can cost around $600 to $700 to make a ventilator.

Although more automation was required for the ventilator to operate properly, Wood said his prototype would still be significantly less expensive and easy to assemble.

Mechanical engineering master’s student, Jack Lucas, assisted professor Wood with the project.

Lucas said despite the initial steep learning curve, he was excited to give back to those in need.

“I was super excited,” Lucas said. “I was kind of hoping that we would turn our lab into something that could help during this pandemic, (but) there were definitely some difficulties … because none of us have worked in healthcare or with any medical devices before.”

Mechanical engineering master’s student, Tyler Lestak, also assisted with the project and said he thinks his experience with electromechanical engine design allowed him to contribute to the project.

“None of us really had any experience in any bio-medical field at all, so it was definitely a big learning curve there, figuring out how ventilators work and all the different aspects,” Lestak said.

While building the prototype, the group wanted to maintain social distancing as much as possible. When they would need to work together in person they would wear masks and gloves.

“We would usually set up the Zoom call in the morning and kind of layout exactly what we wanted to do for the day,” Lucas said. “If we could do some of the stuff from home separately, then we would do that.”

Wood said he was proud of their willingness to help.

“When they heard about the need for this, they very selflessly put their thesis on hold and instead of working on finishing writing their thesis, they started working on this project,” Wood said.

Moving forward, Wood is pursuing funding opportunities to make his system more automated and easy for doctors to operate.

Leave a Reply